Frequently Asked Questions

-

Living Ink is a biomaterials innovator that transforms green agricultural waste into carbon-negative pigments and bio-based inks, replacing the need for carbon black. Our revolutionary product lines, ALGAE BLACK™ pigments and ALGAE INK™ printing inks offer safer, environmentally-smart color solutions for industries worldwide in packaging, footwear, textiles, cosmetics, paints, and beyond.

We create climate-smart products using renewable, living resources from today’s micro-organisms, replacing carbon-emitting fossil fuels in black colorants.

-

Traditional Carbon Black is a harmful powder pigment made from fossil fuels, commonly used to add color and structural stability for the ink, textiles, plastics and rubber industries. Originating from the extraction and burning of dense petroleum substances like oils and tars, it is listed as a Class 2B human carcinogen. The production and use of conventional carbon black is hazardous to human health, causes environmental degradation, depletes finite natural resources, and doesn’t break down naturally. These growing health and environmental concerns led to the development of Living Ink’s bio-based and carbon-negative alternative, Algae Black™, which provides brands with a safe and renewable pigment that resonates with their eco-conscious consumers.

-

Algae Black™ pigments are bio-based and carbon-negative black pigments made from renewable algae waste and other agricultural waste sources. Through our proprietary process, leftover algae and other biomass from farms are repurposed into a powder or suspended liquid form. Algae Black pigment is used to safely color a variety of industrial products such as plastics, rubbers, foams, cosmetics, textiles, and inks (such as our Algae Ink™ collection) to achieve a black or desired shade. Algae Black™ pigment offers manufacturers a sustainable, drop-in replacement for traditional, petroleum-derived, carbon black pigment.

Learn more HERE.

-

Algae Ink™ is our flagship product line of innovative and environmentally-friendly printing pastes. Algae Ink is made by mixing our carbon-negative Algae Black™ pigment powder, with a base carrier (like water or soy) to create liquid or paste inks that can adhere to various consumer products. Algae Ink products are used in various printing applications such as offset, flat bed and rotary screen, and flexographic printing projects to achieve a high-performance, black color. The collection includes a number of ink variations that can be utilized for different printing applications including packaging, apparel and footwear.

See our full list of inks available HERE.

-

Why biomass waste? Because it’s 𝙡𝙞𝙫𝙞𝙣𝙜 𝗰𝗮𝗿𝗯𝗼𝗻—derived from sustainable and replenish-able resources 𝗹𝗶𝗸𝗲 𝗮𝗹𝗴𝗮𝗲 and other natural byproducts—not 𝙛𝙤𝙨𝙨𝙞𝙡 𝗰𝗮𝗿𝗯𝗼𝗻, which adds environmental burden.

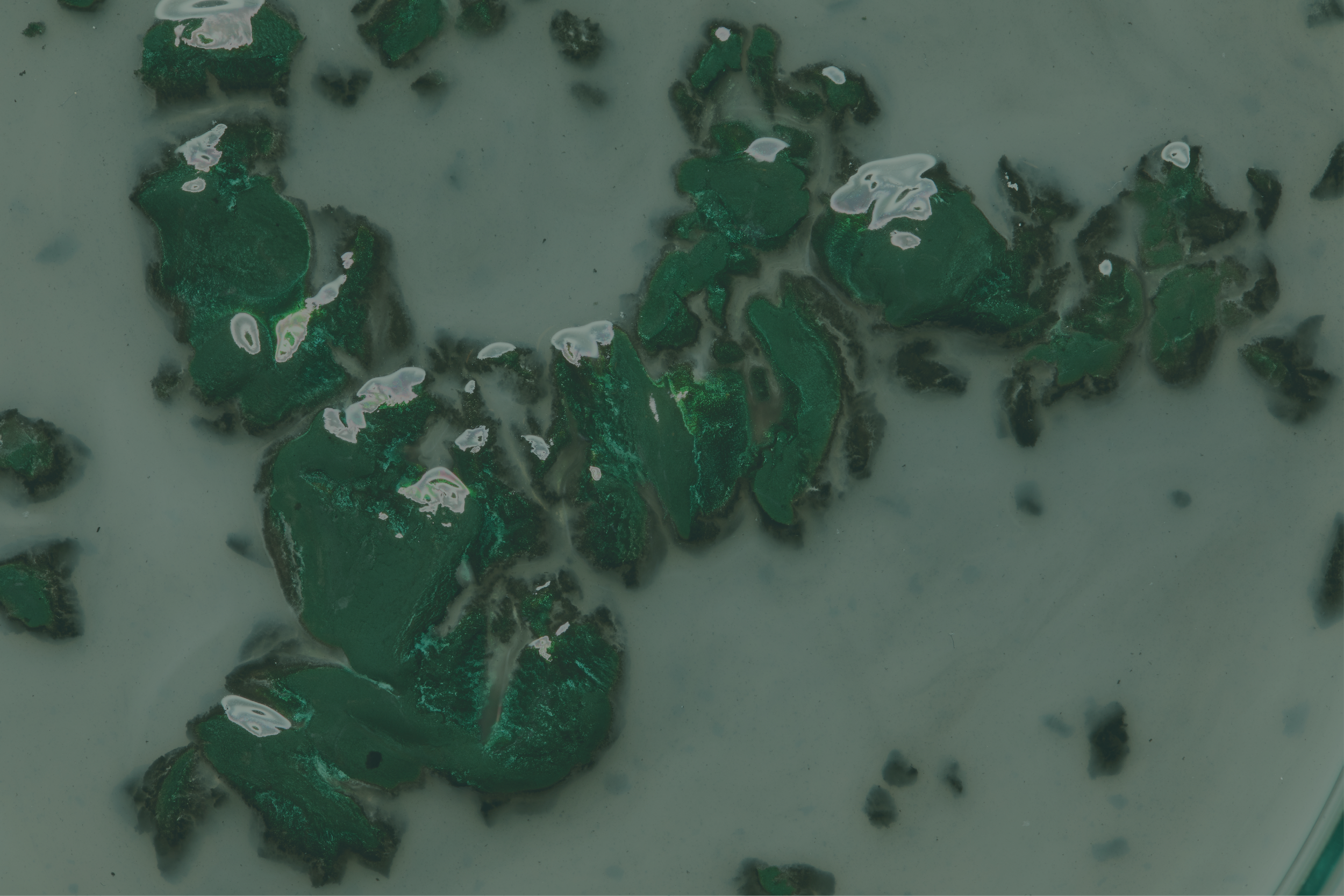

Algae is one of the most productive and prolific plants on earth. Grown using sunlight as power and CO2 as building blocks, algae naturally sequesters CO2 from the atmosphere. Algae also creates massive amounts of oxygen. For example, over half the oxygen we breathe comes from oceanic algae. Growing algae requires minimal land and less water usage compared to traditional crops, ensuring zero contribution to deforestation or the displacement of land and other resources for food production.

Living Ink, specifically uses algae waste from farms as we provide a responsible waste disposal solution for our partners who are already cultivating algae for purposes like wastewater treatment and dietary supplement production.

-

We make a soy ink formulation. It is our Offset Algae Ink. The difference between our soy inks and conventional soy inks, is that we swap out fossil fuel-derived pigment (carbon black) with our algae-derived pigment (Algae Black).

image|offset image|/s/How-our-soy-ink-OFFSET-ALGAE-INK-is-made.jpg

-

Pigments are dry, solid color particles used to create the hue in products (like inks), while ink itself serves as the liquid medium to transport and bind these pigments onto various surfaces; for example pigments are essential for formulating vibrant hues in paints, cosmetics, plastics, and textile products. Inks are commonly employed in printing processes like offset, screen printing and flexography for packaging and trims projects. Living Ink offers both Algae Black™ pigments and Algae Ink™ printing inks for our partners. CONTACT US to inquire about placing a bulk order or visit our SHOP PAGE to purchase sample quantities shipped within the US.

-

No, we do not produce reactive black dyes or sulfur dyes. While some partners have utilized our Algae Black™ Pigment for garment dyeing, it's important to note that our product is a genuine pigment, not a dye. If you are already using traditional carbon black pigment in your garment dyeing process, Algae Black™ may be a solution for you.

-

Living Ink partners with farms to divert agricultural waste away from landfills and repurpose it into sustainable black pigment. To create our flagship Algae Black™ pigments, we work with growers like California-based algae farm, Earthrise Nutritionals, to collect algae biomass leftover from their natural nutritional supplement production. The algae biomass then undergoes a proprietary thermal treatment process and is converted into our carbon-negative and bio-based black colorant.

-

We exclusively produce black color at this time. Our black pigment meets the performance expectations of traditional carbon black in its intensity and resistance to UV light degradation, meaning it won't fade. Sign up for our newsletter to be notified about new product releases and expansive color options as we reintroduce a range of colors in the future.

-

No, Algae Ink™ serves as a drop-in replacement for carbon-black-based inks, making it compatible with your existing printer equipment. Developed by Living Ink's chemists, our ink formulations are user-friendly—they store, print, and clean just like conventional petroleum-pigmented inks. Whether you choose to collaborate with Living Ink's printing partners or suggest Algae Ink™ products to your current printer, the transition is uncomplicated. Living Ink or our trusted distributors manage ink production and distribution to ensure a practical and accessible integration.

-

Certainly, we maintain a growing list of preferred printer partners globally who have successfully trialed or commercially produced projects with our ink, spanning across packaging, magazines, brochures, business cards, hang tags, tape, and more.

If you are a brand looking to incorporate Living Ink into your product line, we can recommend suitable partners for sampling. If you are a manufacturer interested in becoming a preferred printing partner, please CONTACT US for more information or to place a sample ink order.

-

Following a comprehensive Life Cycle Assessment (LCA) conducted by a third-party ISO certified team from Colorado State University, we've confirmed that our Algae Black™ Pigment achieves carbon negativity at large-scale production. This carbon-negative status indicates that the manufacturing process of Algae Black, removes more carbon from the environment than it contributes, resulting in a positive environmental impact.

This achievement is made possible by our repurposed algae raw materials absorbing atmospheric carbon dioxide, with Living Ink effectively "locking" that absorbed carbon into the bio-based black pigment particles for over 100 years.

-

Every kg of Algae Black™ we produce keeps ~3 kgs of petroleum (crude oil) from being used. Additionally, because our pigment is carbon negative, using a 1 kg of Algae Black™ can remove -4 kg of carbon dioxide.

-

Our team is regularly sending large-volume, palletized orders around the world. We can accommodate various order quantities. CONTACT US to learn more about bulk ordering and lead times for your specific project.

-

No, we are not a domestic packaging company, nor do we offer printing services in-house. Please connect with us to be introduced to our existing printing partners to inquire about sampling and commercial production opportunities with our bio-based pigments and inks.