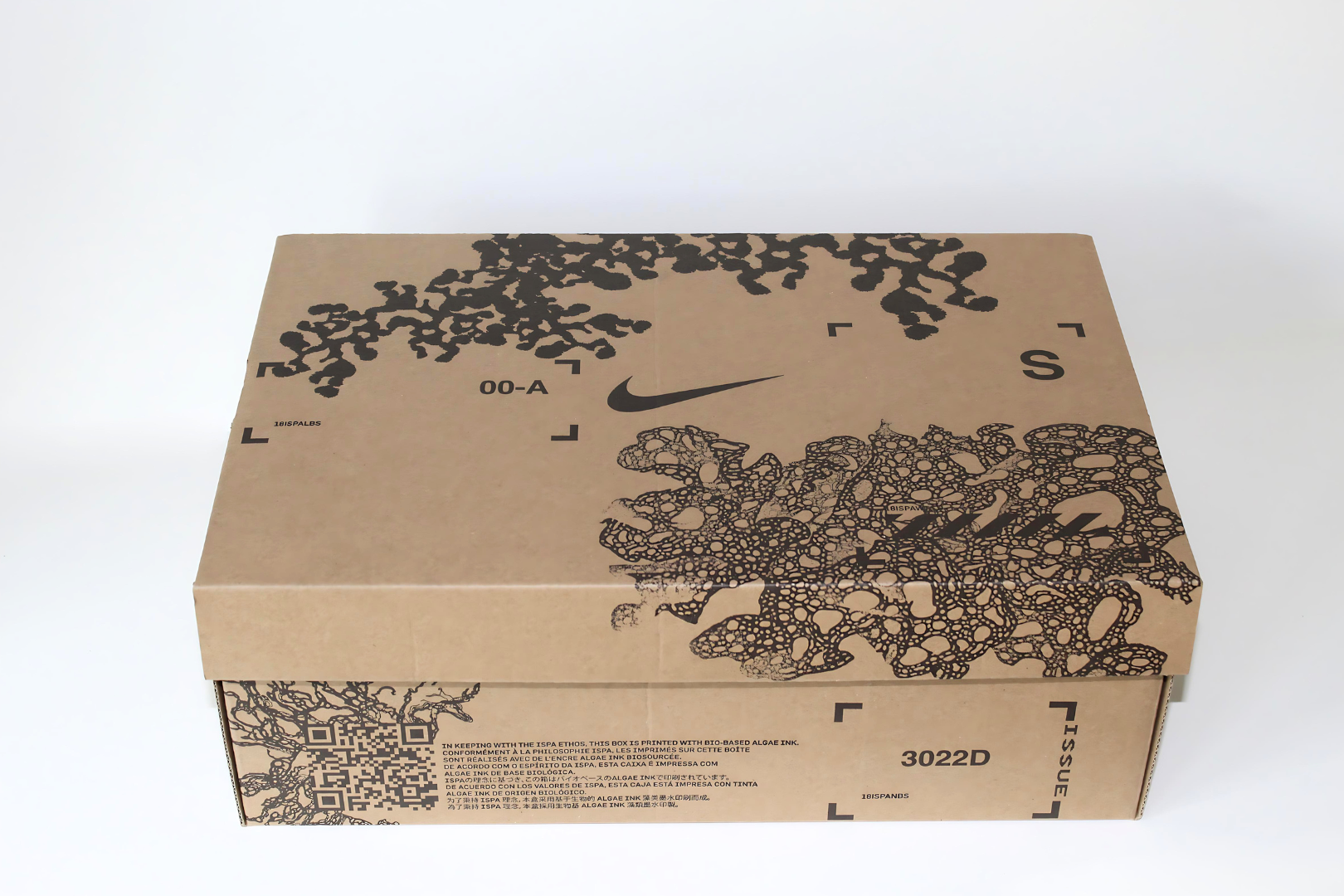

Packaging World: Nike Uses Algae-Based Ink to Decorate Footwear Box

Nike uses a carbon-negative black pigment-based ink made from renewable algae waste to decorate a footwear box for sub-brand ISPA. By —Anne Marie Mohan

With a design philosophy of “Improvise, Scavenge, Protect, and Adapt,” Nike sub-brand ISPA recently introduced a new shoebox that demonstrates its commitment to sustainability and cutting-edge innovation. Rather than using ink made from petroleum-derived carbon black to print the footwear box, Nike is decorating the package with Living Ink Technologies’ water-based, algae-pigmented ink, Flexographic Algae Ink.

As Living Ink explains, traditional carbon black is a powder pigment made from fossil fuels that adds color and structural stability to inks, textiles, plastics, and rubber. Despite its effectiveness, however, its use of fossil fuels results in both environmental and human health risks.

“Originating from the extraction and burning of dense petroleum substances like oils and tars, it [carbon black] is listed as a Class 2B human carcinogen,” says Living Ink. “The production and use of conventional carbon black is hazardous to human health, causes environmental degradation, depletes finite natural resources, and doesn’t break down naturally.”

To address these issues, Living Ink developed a bio-based, carbon-negative black pigment called Algae Black made from renewable algae waste and other agricultural waste sources. Through a proprietary process, the company repurposes the leftover algae and biomass from farms into a powder or liquid suspended form that is used to color a variety of industrial products, including its Algae Ink.

According to Living Ink Director of Partnerships Devon Murrie, a life-cycle analysis conducted by Sustainability Science and Colorado State University in January 2023 showed that the production of Algae Black pigment is a carbon-negative process calculated to reduce CO2 equivalent emissions by 200% compared to carbon black pigment. “Every kilogram of Algae Black pigment we produce keeps approximately 3 kilograms of petroleum from being used,” she says. “Additionally, because our pigment is carbon negative, using 1 kilogram of Algae Black can remove 4 kilograms of carbon dioxide.”

Nike began working with Living Ink in 2021, using its Standard Screen Algae Ink to screen-print items such as footwear and t-shirts. According to Murrie, Nike chose Algae Ink made from water and Algae Black for the ISPA project because “it was in line with the sub-label’s ethos.”

Introduced in late spring 2024, the ISPA footwear box is flexo-printed with depictions of various types of algae. Murrie shares that Living Ink collaborated on the project with an approved printing partner from Nike’s existing suppliers based in Vietnam. “We worked with the manufacturing group to ensure our ink was able to hit the jet-black color specs requested,” she says. “Overall it was a drop-in solution to conventional flexo ink.”

To inform consumers of its use of the algae-based ink, Nike added a QR code to the box that, when scanned, directs consumers to a TEDx Talk by Living Ink CEO Scott Fulbright, titled, “Is algae the ink of the future?,” which highlights the genesis and early stages of the company. The inside of the lid also provides the scientific names of each type of algae illustrated on the outside of the lid.